Product Center

Double Acting Pump is used for well with high reservoir pressure and sufficient liquid supply, especially those where conventional pumps cannot meet the displacement requirements.

The leather bowl support connector is connected to the tubing pump hanger design position. The length is going to be 6 in length. Up to 14 inches.

The pump anchor designed and developed by Weima is used to let the rod pump seal in the tubing, not use the conventional seating any more. It can also be used in oil wells that must constantly adjust the pump setting depth of rod pump as the supply level changes to improve production efficiency.

The upper joint of the pump barrel is a standard part of the rod type oil pump.The upper part is connected with the stem guide sleeve and the lower part is connected with the pump barrel or lengthened.

The upper open bonnet is standard on tubular pumps.The upper part is connected with the sucker rod string, the lower part is connected with the plunger, and the traveling valve is placed in it.Material selection and structural strength are the key factors in product design.In order to strengthen the protection of the valve hood, there are alloy lined valve hood designed for thermal production and high flushing oil Wells.There is a rubber lined valve cover designed for cold production and high stroke oil Wells.

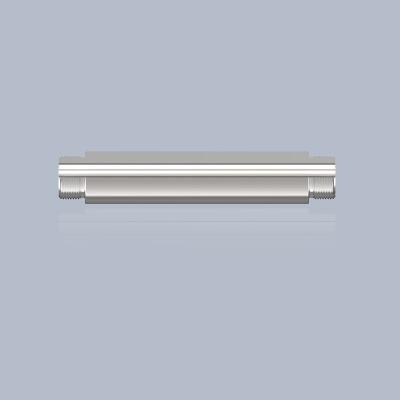

The stem reducer joint is a standard part of the sucker rod pump and connects the upper stem of the plunger to the rod string.The connecting part with the valve stem is the key to the structure of the product. The more likely problem to occur is the breaking off of the connecting valve stem.Therefore, its material’s selection and structural strength’s design need to fully consider the product’s operating environment.