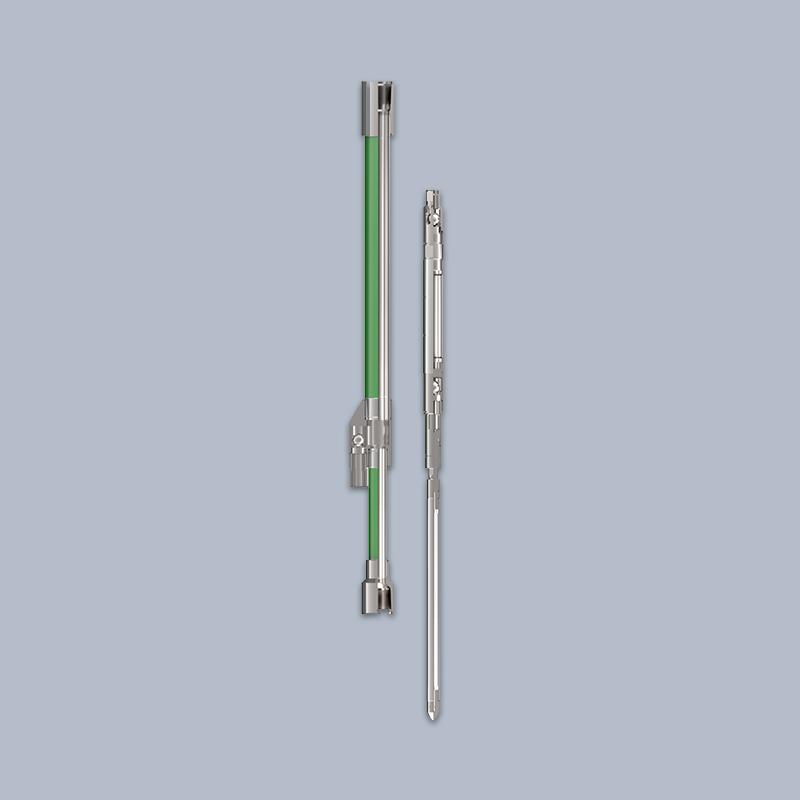

Characteristic:

The upper and lower barrels and the upper and lower plungers are connected in series connection to form a sealed pump cavity. The oil inlet valve is set at the side of the pump body. During the down stroke, the upper plunger oil outlet valve is closed to achieve the purpose of hydraulic feedback force.

The pump does not need to be installed with a drain device, the sucker rod can be lifted for downhole testing, steam injection thermal recovery and oil drain operations.

The selection of fittings materials, various heat treatment processes and surface treatment processes can be applied to meet the requirements of well conditions for product strength, corrosion resistance and wear resistance.

Product Specification:

| Tubing Size | 2-7/8” | 3-1/2” | 3-1/2” |

| Pump Diameter | 2 1/4”-1 1/2” | 2 3/4”-1 1/2” | 2 3/4”-1 3/4” |

| Barrel OD | 4.500” | 5.250” | 5.250” |

| Sucker Rod thread | 3/4” | 7/8” | 7/8” |

| Connecting Tubing Thread | 2-7/8”-8EU | 3-1/2”-8EU | 3-1/2”-8EU |

| Code | 25-225/150PFK | 30-275/150PFK | 30-275/175PFK |

Displacement:

The calculation formula of displacement is as follows:

P=C×S×N

P:Daily displacement, BPD;

S:Stroke length, in;

N:Frequency of strokes per minute, times/min;

C:Pump constant, as follows:

| Pump Diameter | 2 1/4”-1 1/2” | 2 3/4”-1 1/2” | 2 3/4”-1 3/4” |

| Pump Constant | 0.327 | 0.618 | 0.524 |

More information,please download the above PDF brochure.Thank you!