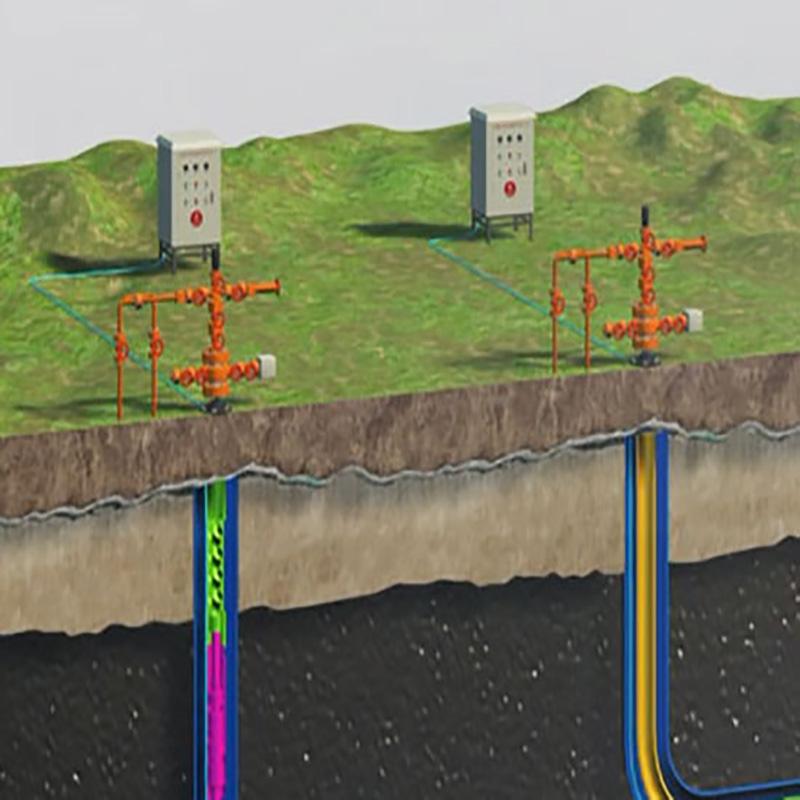

Ⅰ. System Main Parts

The submersible PCP mainly includes: submersible motor and protector, reducer and protector, shaft, PCP, control cabinet and cable.

Ⅱ. Working Priciple

The power is delivered by control system to submersible motor via oil-submersible cable and the motor is driven to rotate. After the motor is decelerated by the reducer at a certain reduction ratio, the power is delivered to screw pump and the screw pump is driven to rotate. Then liquids are realized the liquid lifting.

Ⅲ. Movement Features

● No movement parts on the wellhead, sealing type is static seal, ground safety, environmental protection.

● No movement parts in tubing, no abrasion between rod and tubing, to improve the service life of the tubing.

● The submersible motor is connected to the screw pump after being decelerated and increased by the reducer.

● Under the environment of water or crude oil, has good adaptability to the fluid, no gas corrosion and no gas lock, and can work efficiently in high viscosity crude oil.

● Adapt to various well condition to lift the oil.

Ⅳ. System reliability

● According to the well condition to design system scheme, the equipment customization mode is implemented.

● The temperature resistance of the system can reach up to 200 °C.

● The torsion strength of the reducer can reach up to 1200Nm, which meets the requirements of the screw pump operation.

● The protector adopts a double capsule single sedimentation cavity structure to effectively isolate the well fluid and balance the internal and external pressure difference.

● The cable uses downhole special armored cable and can be optimally configured for internal materials according to the well conditions.

● The screw pump adopts oilfield special rubber and special processing technology to ensure the running torque and volumetric efficiency.

Ⅴ. Technical Parameters

| Specification | Head(m) | Rotation | Theoretical displacement(m³/d) | Motor | Voltage level (V) | OD (mm) |

| QYLB28-27 | 1000 | 70-150 | 2.8-6 | 15 | 140-3600 | 114 |

| QYLB28-40 | 1800 | 70-150 | 2.8-6 | 15 | 140-3600 | 114 |

| QYLB40-27 | 1000 | 70-150 | 4-8.64 | 15 | 140-3600 | 114 |

| QYLB40-40 | 1800 | 70-150 | 4-8.64 | 15 | 140-3600 | 114 |

| QYLB40-50 | 2000 | 70-150 | 4-8.64 | 15 | 140-3600 | 114 |

| QYLB75-27 | 1000 | 70-150 | 7.56-16.2 | 30 | 140-3600 | 114 |

| QYLB75-40 | 1800 | 70-150 | 7.56-16.2 | 30 | 140-3600 | 114 |

| QYLB75-50 | 2000 | 70-150 | 7.56-16.2 | 30 | 140-3600 | 114 |

| QYLB120-27 | 1000 | 70-150 | 12-25.9 | 30 | 140-3600 | 114 |

| QYLB120-40 | 1800 | 70-150 | 12-25.9 | 30 | 140-3600 | 114 |

| QYLB160-30 | 1400 | 70-150 | 16-34.5 | 30 | 140-3600 | 114 |

| QYLB200-27 | 1000 | 70-150 | 20-43 | 30 | 140-3600 | 114 |

Notes: The above is a list of some specifications, customized processing according to customer requirements.