Product advantage:

Environmental protection

Energy conservationSafe and efficientRemote management system

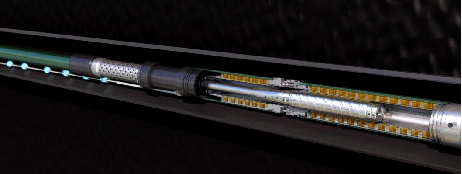

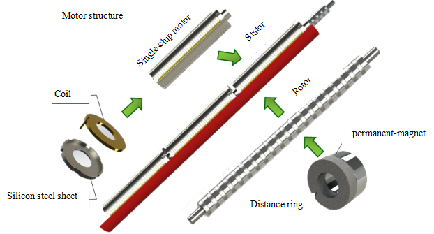

Linear motor pump intelligent oil production outfit is composed of three parts: control cabinet, submersible linear motor, plunger pump. The power is transmitted to the stator of the downhole linear motor through the cable. The stator produces strong magnetic force, drives the rotor, and moves up and down according to the required speed under the instructions of the ground control cabinet. The upper end of the rotor is connected with the special tubing pump plunger to move up and down to realize the downhole liquid lifting.

Environmental protection

There is no movable equipment on the ground, but only control cabinets and Christmas trees, without noise. It is suitable for oil well exploitation in residential area.

Energy conservation

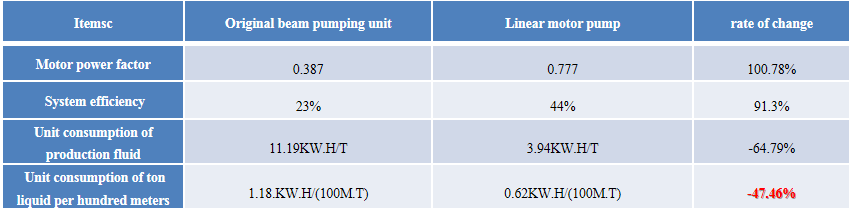

Intermittent power supply, short power supply time, significantly reduced energy consumption; The working energy consumption of the oil beam and sucker rod of the pumping unit is removed, and the drive of surface pumping unit with the sucker -rod pump is changed into a downhole linear motor to drive the oil directly, and the energy consumption is further reduced!

According to the test data, compared with the eight type pumping units, when the daily production of liquid is less than 2 t, the daily electricity is saved more than 80%; when the daily production of liquid is 2-5 t, the daily electricity is saved more than 60%; when the daily production of liquid is 6-8 t, and the daily electricity is saved more than 40%!

Safe and efficient.

Routine maintenance items | Pumping unit lifting | Electric submersible plunger pump |

Anticorrosion and insulation | ✔ | ✔ |

Inspection of oil leakage, bleeding, dripping, spilling | ✔ | ✔ |

Routine maintenance | ✔ | ✘ |

First -class maintenance | ✔ | ✘ |

Second- class maintenance | ✔ | ✘ |

Belt replacement | ✔ | ✘ |

Addition of packing | ✔ | ✘ |

Adjusting balance, stroke and rate of pump | ✔ | ✘ |

| Linear motor | |||

| Type | permanent-magnet linear motor |  | |

| Outer diameter | φ96mm, φ114mm, φ143mm, | ||

| Length | 4.46~10.9m | ||

| Working medium | mixture of oil, water and gas | ||

| Bearable downhole medium temperature | ≤150℃ | ||

| Bearable downhole environmental pressure | ≤30Mpa | ||

| Rated input voltage | 380V, 660V,1140V three-phase four-wire system | ||

| Input Frequency | 50Hz | ||

| Max output power | 50KW(114 series);80KW(143 series); | ||

| Work schedule | intermittent | ||

| Insulation grade | H | ||

| Maximum thrust | 3.5T(114 series) 6.0T(143 series) | ||

| Stroke of stator | 1.23 m, 1.47m | ||

| Cooling mode | well fluid flow cooling | ||

| Intelligent control system | |||

| Working voltage | 380V, 660V, 1140V | ||

Parameters can be adjusted online at will | 0.1-8 times/min | ||

| Level of protection : | IP65 | ||